Cores and Pours

Cores and pours is an MMW original technique combining custom made ferrous insert cores encased in poured bronze. This technique allows for an infinite amount potential complexity or simplicity of contrasting colors, forms and patterns. This bimetallic casting process developed my MMW requires an that an extensive amount of preparation be put into the mold and its other features. Each Pour is then manually machined to yield a unique piece of stunning contrasting metal elements.

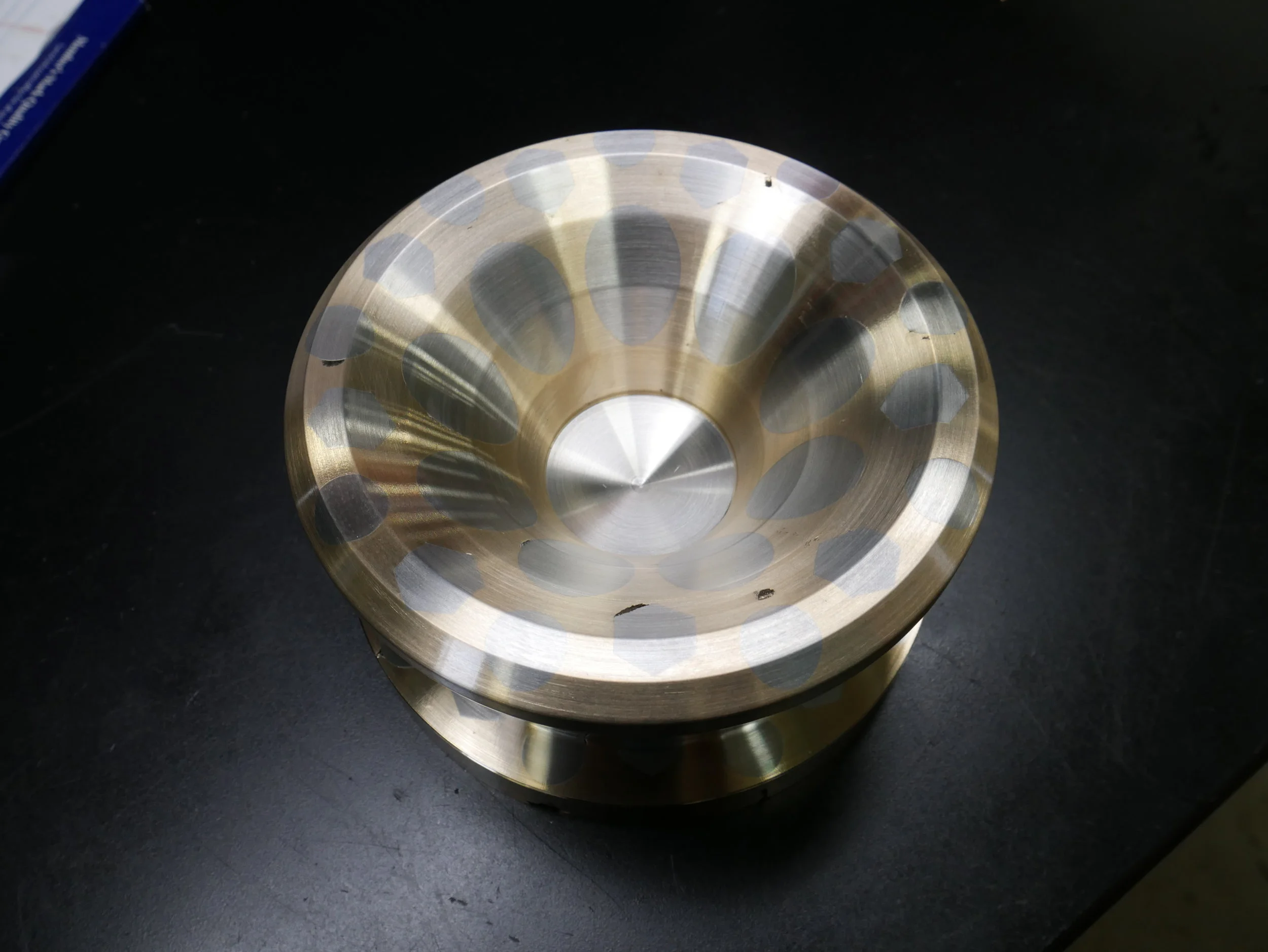

Shown here is a prototype pour in the lathe following rough machining. This example used a variety of sizes of round and hexagonal stainless steel inserts arranged in a radial pattern. The materials used also permit repair of any casting defects via Tig welding. This technique is adaptable to a wide range of form factors, such as decorative platters, bowls, lamp bases, or nearly any other machinable shape.